TL;DR Don’t currently know what the issue is. Asking for assistance from the world.

Welcome to an info dump I’ve been working on for a few weeks. No amount of google foo seemed to be coming up with the answer I sought so I’m putting my data/tests/findings on the inter-webs in the hopes that someone will comment a suggestion/fix, or that anyone else with a similar issue may find an answer for their very particular issue hidden in among these ramblings.

Current update: 2025-08-05

For mainly environmental and health reasons I am not planning on removing or gutting the DPD, especially as photos and data seemed to be pointing to another unknown item in the system being at fault.

Back Story.

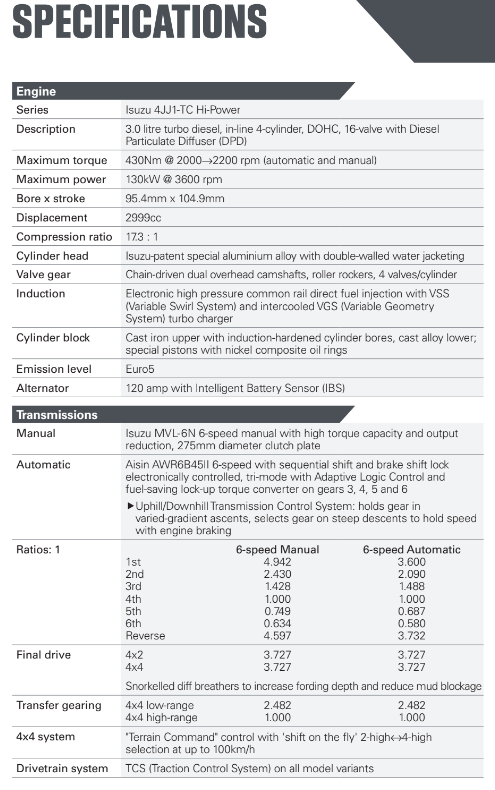

I purchased one of the then unbeknownst rare model Isuzu MU-X from an Australian Isuzu Ute Dealer New in 2017. The MY16.5 MUX was the first model with the tuned up 4JJ1-TC Hi-Power (sic) Engine. The Euro 5 Emissions rated, 3.0L, 430Nm, 130kW spec engine and the added gear Aisin AWR6B45II 6-speed Automatic Transmission. It was a filler model that kept most of the MY13-MY16 exterior look, but got the upgraded engine, 6 speed transmission and, as with the purpose of this write-up; the DPD system to meet Australia’s slow push towards Euro6 standards. It was imported and sold for the first few months of 2017 as a gap filler until the “new look” MY17 model was announced in May and released in June. Based on some of the VIN’s I’ve seen, all starting in “MPAUCS85GHT######” or “MPAUCR85GHT######”, only around 900 were imported. The factory model code looks to be UCS85 for the 4×4 and UCR85 for the 4×2

Timeline.

The selling dealer completed all maintenance up to the 150k service. The Turbocharger threw an over boost DTC code around 65k and was replaced under warranty. No major unsorted issues along the way. Local mechanic and own maintenance schedule run from the 160k service onward.

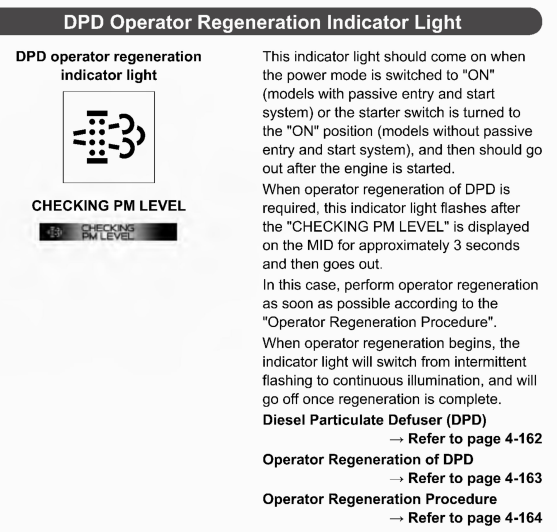

Just before the 200k service we were returning from a family wedding in Cairns. Got a 3 beep code from the dash and a “Checking PM Level” popup on the gauge cluster screen. Then the regens started. First around every 80-100km. The DPD level bar graph would just from 0/5 to 4/5. Then to 5/5. Sometimes with another beep and message. Sometimes without.

We consulted the owners manual on-trip. It indicating that 4th gear, at least for the start of the regen cycle to help it get up to temperature may assist with the regen. Going forward I followed this procedure. Running around 2 gear’s under the most efficient (without it exceeding 2800rpm) for the first 20% of the regen and then 1 gear under most efficient for remainder. Trying to maintain a constant speed/load. But as you can understand this can be extremely difficult with with varying terrain and traffic.

At the end of that days travels I also checked in on how the DPD may be blocked, causing these issues.

We had just spent several days getting to Cairns. Almost entirely highway driving at highway speeds. My vehicle usage pattern doesn’t fit the bill for one that would normally get a blocked dpd this early in its life. Limited towing, mainly with an unbraked 750kg trailer when rarely do. We travel long distances for holidays, but in a single vehicle with a roof top tent touring configuration, I travel between my workplaces locations most weeks. Covering at min 30km a day. At max 200km. The vehicle has never idled for a long period and if anything the vehicle DPD be doing great after a 500km day with 5-7 regens. A quick google says a fuel additive may lower the temperatures required to correctly regenerate the DPD. Purchased and added a Penrite DPD Cleaner at next fill. KMs between regen rose slightly, but it still threw the “Checking PM Status” beep code every 60-120km.

Returned from that Cairns trip frustrated and not knowing where to turn next.

Its now 14 months later. KMs between regens have been reducing at a pretty steady rate to the point of it being sometimes 6km between and though the vehicle doesnt feel underpowered. And never does the vehicle power level change across the few km of not regening vs is. It doesn’t quiet feel new anymore.

For a time in the middle of the past 14 months I just started ignoring it. Slightly higher fuel usage, with all the regeneration, but no show stopping errors along the way.

Over the 2024 Christmas period and with my being from an IT and analytical background I built my own OBD based data logger and have been live viewing/recording to a database all critical vehicle stats since. I’ve learnt a lot, but not quiet enough to resolve the issues of this vehicle.

The data logger is a Can-Bus hat on a Raspberry Pi 4. Python for the language and a little WSGI server for live data display in a web browser. Zabbix network monitor for the real time data logging and graphing.

Some key info found along the way (to my best knowledge):

– Under normal operation the DPD accumulates particulate matter, mainly burnt off soot, mostly carbon particles. These carbon particles exit the exhaust manifold at mainly the nano-partical size. If released directly into the air they can have a similar, but a slower accumulation rate, effect to Asbestos fibres in Human and Animal lungs. In short not good. The DPD/DPF is able to collect this super fine soot particles and forces them to clump onto the ceramic DPD filter core into larger groupings. When the regeneration runs it purposely ups the exhaust gas temp to a level that will dislodge these larger, now carbon micro-partials, into the exhaust stream. Particles of this size are either too heavy to remain airborne and fall to the environment or are large enough to filtered out by the lungs of humans and animals. Reducing, but not eliminating, the effects of diesel engines. The DPD/Cat also assists in reducing NOx gases.

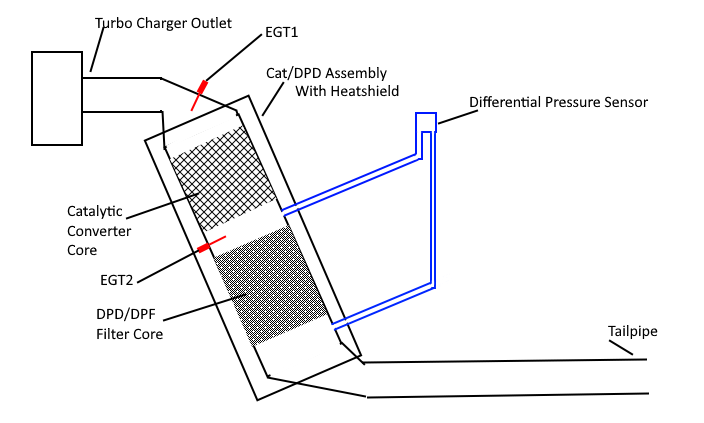

– In this Isuzu I’ve determined the setup is as follows.

Based on Exhaust flow the gases travel.

Through the Exhaust manifold >

Spin up the turbo charger hot side >

into the DPD/DPF Stack >

– Pass an Exhaust Gas Temperature (EGT) Sensor,

– followed by the Catalytic Converter Core,

– a second EGT, and a port for the DPD Differential Pressure Sensor Line,

– the DPD/DPF Filter Core itself,

– and then a second port off the exhaust flow for the other side of the pressure sensor.

– The exhaust flow then continues back through the silencer and out the back of the vehicle.

– The EGTs, specifically the lower one just ahead of the DPD let the ECU coordinate the exhaust temp to effectively regenerate the DPD.

– The two pressure sense ports, hardline tubes and then softline tubes connect to a chassis mounted “DPD Differential Pressure Sensor”. This smart little expensive device looks at its two input tubes pressure. And will report to the ECU only the difference in pressure across the DPD, in the form of a voltage which is then converted to kPa (kilopascals). This is effectively the DPDs resistance to flow, or how much soot has accumulated. The higher the level. The higher the pressure difference before vs after the DPD.

For my own vehicle, which may currently be at fault, at idle this diff pressure sensor will show a value between 1 and 2 kPa or 1-2% of an atmosphere of pressure. Under constant loads, and again without knowing the internal state of my DPD, I’ve seen values in the 6-10 kPa range with the cruise set between 60 and 100kmph. Under heavy acceleration, its peaks in the 35kPa area.

The diff pressure value being more related to engine rpm and airflow, rather then vehicle speed.

The vehicle uses a mix of data to determine when it should next regen.

Including:

– Distance since last regen.

– Loads seen since last regen.

– A somehow averaged or normalized (?) DPD diff pressure sensor value. And how much higher is it now compared to at the end of the last regen. (Update: this variable being so jumpy may be more related to a faulty turbo)

– The temps seen during the last regen to ensure it burnt of the majority of the accumulated matter.

If any of these values indicate a high PM Level, and the conditions are right, it will initiate an automatic regeneration. If this happens frequently it will alert the user at each instance.

During a regeneration the vehicle looks to target a lower EGT Temp (the one between the Cat and DPD) of 600°C. It does this by injecting additional diesel fuel into the cylinder during it exhaust stroke. The fuel is instantly ignited by the hot and high press exhaust gases and the bundle is sent off through the turbo, then to the DPD stack. Note during a regen the EGR Valve remains at 0% or closed. So the cooler body isn’t exposed to these super hot gases.

It is unable to do this addition fuel injection constantly or the EGT would jump to way above 600°C.

Instead it looks to do it in stages, and only when engine load is relatively stable, such as when traveling a near constant speed. Just set the cruise and watch the temps rise. First from normal temps in the 300-430°C range up to low 500s, then slowing as it reaches 600. Due to the distance between heat generation and the DPD stack, plus a (at least likely misunderstood by me) temperature increased as exhaust gases flow over the Cat; Ive seen it occasionally overshoot. Mainly when it just hit 600 and you ease off the pedal. It can peak to 635°C for a second or two before it drops again. Once it hits 580 it looks to turn the additional squirts of diesel back on for a moment or three. Under a constant load it’ll stabilize and float around 600. On a good day with a solid road and limited traffic it can sit in the 580-610 range from around 40 seconds into the regen right until the end.

If stopped, and sitting with the transmission in park/drive, it is also able to raise the temp to 600 slowly and then maintain until the end of the regen. From my understanding this is okay, but less then optimal as with limited airflow at idle a percentage of the PM will remain attached lacking sufficient air flow to be dislodged.

Bellow is a list of potentially causes discovered, or fixes attempted. And a brief explanation of each.

Fuel additives, DPD Cleaners etc, sometimes increased distances between regens but not for long and not once the tank was empty and refilled without the additive. For my particular issue I shouldn’t have wasted so much time or coin on additives. Tried both of the Penrite options, the consumer range and Convo range products. Plus Liqui Moly. And Nulons offering. They may help with actual blockage issue, but my problem didn’t look to be caused by that.

Chemical cleaning, The Penrite foaming spray can DPD cleaning agent added through the upper diff pressure sensor hardline port, and then a manual OBD Computer triggered long regen + associated oil change. Completed this process once. Also did a DPD Data clear, Oil Dilution Clear and DPD Dilution clear with the same OBD computer. Increased time between regens for a few days, but slowly came back down to 10km as the ECU encountered the same unknown fault and adjusted the DPD Dilution to suit.

Diff Pressure Sensor Fault.

I’ve Inspected/tested the DPD diff pressure sensor and pressure tested the soft/hardlines. Have completed this multiple times. A Daytona D9006 Vacuum and Pressure test kit can assist you here. Test either only the softlines by removing them, plugging one end and placing the pump/gauge on the other. Pressure or vacuum to around 1 bar,( ~100kPa) and let it hold for 5 minutes. Check for any pressure change that may indicate a leak. If you’re real keen you can also test the lower hardline by unbolting the exhaust pipe from the bottom of the dpd stack, temp blocking the port with a rubber plug and testing at the softline from the top end.

The remote end of the upper hardline is situated between the DPD and Cat and is inaccessible. The hardline itself can be removed, check its soft seal for leaks/dirt/rust.

With an OBD computer connected to the vehicle you can also crudely test the diff pressure sensor itself. Disconnect both soft lines from the hard lines and leave them attached to the sensor; leave the sensor plugged into the vehicle but unbolt it from the mount for easier movement. Attached the hand pump and gauge to one line, pump to around 0.5bar (50kPa) and hold for 10 minutes. Check readout on OBD computer. It should match gauge. If value on OBD Computer is -50kPa this is the expected value for the other side of the sensor. I don’t recommend any higher then 0.5bar as that is about the max the sensor should see under normal use. Any higher may damage it.

Sensor Wiring

I spent an afternoon tracing each of the 3 wires from the DPD sensor, back through the loom to a connector on the ECU. All 3, the Ground, 5V and signal wires all showed less then 0.1ohm on a resistance check. Most of that coming from the adapted piece of copper wire I had to get into the ~40pin connector that is normally plugged into the ECU. Did the same for the MAF just in case. Not a wiring fault.

If running this test. Power off the vehicle and wait at least 2 minutes to let the ECU fully complete its shut down process, then disconnect the battery before pulling any connectors or plugs.

Known Codes.

I was warned to keep an eye out for DPD Codes P2453 or P2002 as they may indicate a diff pressure sensor failure. With either of these codes, and a younger vehicle you should be able to get it replaced under warranty. Have seen neither in my case.

Code P1471 I have seen. DPD Insufficient Regeneration is the description for this code. Only occurred on a longer day stretch during a recent trip. And happened shortly after what could be considered perfect conditions for a regen. 110 on a remote highway. Cruise control set. Flat and no traffic. EGT easily hit and sat at 600 in 5th gear for a few more revs. But still threw it. And then limited engine rpm to 2000 after throwing. Was able to clear code with an OBD BT Dongle, shutdown engine for a minute to let the computer restart and get going again but having it occur 3 times in one day is infuriating.

If you get a Code P1471. And you have the same fault as my vehicle. You can restart the computer to remove the limp mode and cruise control disable. By turning the car off for about 3 minutes.

And then drive with the engine light on, and it wont regen. For the extent of a long trip I did this a few times. Let it code. Stop/restart. Drive for around 100km to let the PM actually build up. Reset the stored codes. Regens straight away. After a few days of it doing regens every 6km. This was bliss. Until it throw a new code on me P242F – “Diesel Particulate Filter Restriction – Ash Accumulation”. Which not only puts the vehicle in limp mode, but also locks your transmissions in whatever gear it was in and forces you to pull over. Thankfully this happened near home and not while on a trip. Was able to reset on the side of the road and make it the 15km home. Let it cool overnight and re-inspected the DPD with a scope the following morning. No visual change to the borescope check from a few weeks prior. No high level of ash accumulation. Just the same error without a known cause.

Mass Air Flow (MAF) sensor

As suggested by one mechanic the MAF may be giving incorrect values, without going outside its normal range and throwing the related code (Don’t know what this code is). This could result in some loss of performance and make the ECU believe the DPD is clogged.

Borrowed a MAF with less then 20,000km on it and confirmed with my data logger. My sensor was overstating the amount of air being intake by 25-35% under load. Numbers were basically the same at idle through 9-10g/s. This likely caused a higher fuel injection volume to match and threw the actualy air to fuel ratio (AFR) way to rich. Lowering performance, running the engine cooler and increasing emissions. Purchased a new MAF Sensor and installed straight away. Night and day difference in take off performance. Now less likely to drop a gear at small rises in the road. Ill likely just make that a 180-200k service item from now on and can suggest, based on my sample size of one, that you do the same.

Bad Injectors / Replaced Injectors

One of the suggests along the way was 1 or more bad injectors that we not adding fully atomized fuel during the regens. Reducing EGTs to bellow required levels and resulting in incomplete regenerators.

As a part of diagnosing this issue / the 250k service seemed like a good time to replace. I replaced the 4 fuel injectors. Noted a slight increase in performance, plus a 0.72L/100km fuel econ improvement measured across 3 full tanks before and after. Plus my data monitoring showed it was reaching 600 during regens before the replace. The speed that it reaches 600 improved with the injector replacement.

Test/Replace the MAF Sensor first if you’re getting to this stage. I did the MAF second and now Im not convinced the injectors needed replacing just yet.

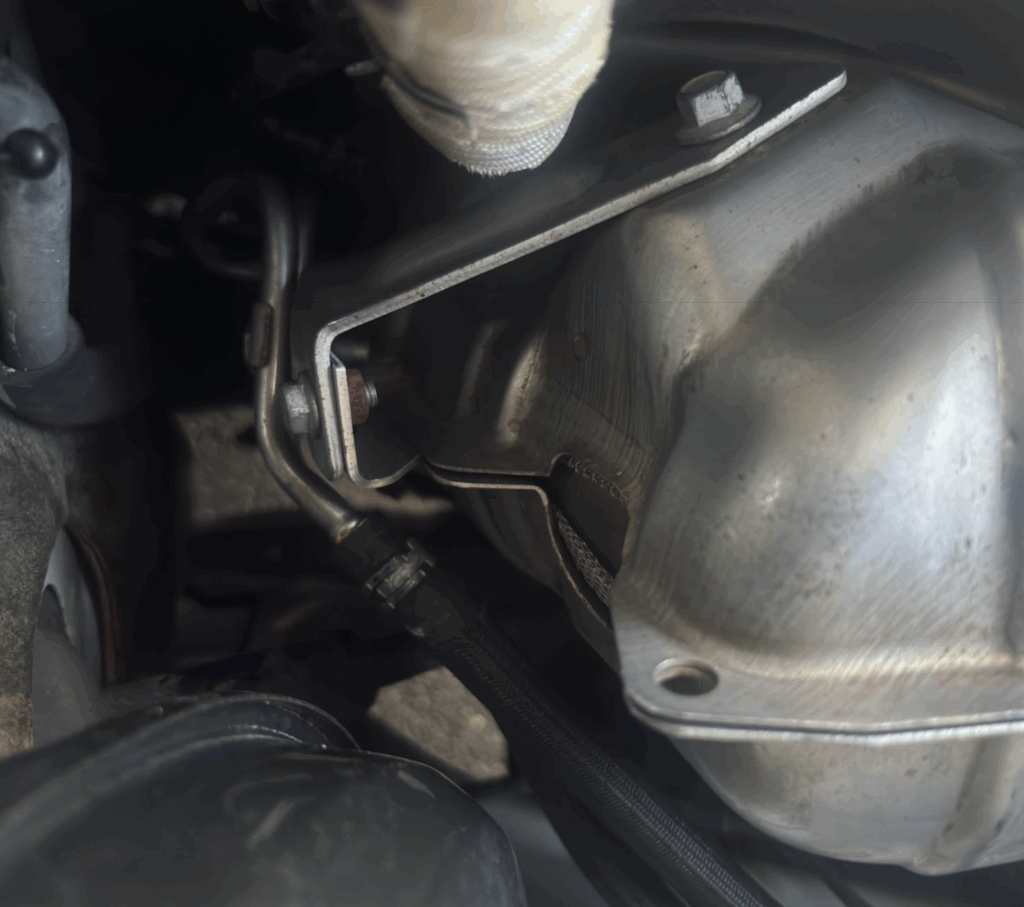

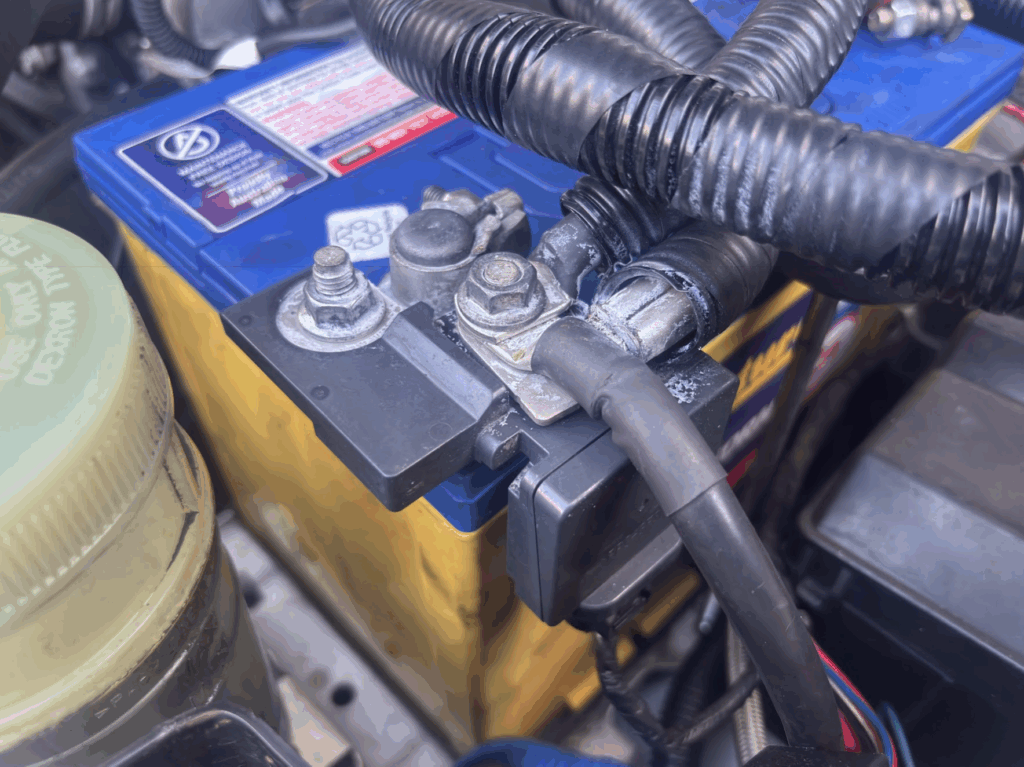

Battery Neg to Chassis Ground Fault

Encountered this one only a short time ago, resolved it but it didn’t resolve the regen issue.

Check for resistance between any chassis ground points (any unpainted body metal) and the battery negative terminal. On a trusted meter you should always get as near as possible to 0 ohms.

Found 16ohm during the initial test. Which on a 12V system is around 10W of power loss. Testing determined this was a dirty connection on the smart alternators current meter.

The first two mating surfaces between the battery post ring and sensor. Disassembly and clean removed all measurable resistance from battery post to main wiring loom. But I still had 1-2ohms resistance to chassis ground.

Traced one of the main copper cables off the sensor over the top of the battery harness towards engine side. And then looping back to the main chassis ground connection just forward of the battery tray. To get at it, its easiest to remove the power steering reservoir hold down bolts and move that out of the way. Unbolted the main chassis ground and found two issues. A dirty connection, and a /factory painted/ mating surface. Gobsmacked by this. The only current pass through would have been between the cable lug and the threads of the hold down bolt, limited surface to surface contact. I lightly sanded back the paint, cleaned up the hooking bolt down point. Tightly mounted it back. Tested to confirm no resistance and one quick spray with you preferred battery terminal protector, dielectic grease, white lithium grease, inox, etc. to protect the connection from corrosion, issue resolved.

Note: After fixing anything to do with the chassis ground I noted that the DPD Diff pressure sensor, which must reference ground across its 5v range, was now 3kPa low. A zeroing, or “DPD Diff Pressure Sensor Relearn” must be completed to tell the car what the sensors new zero level is. OBD Computer with the right codes is required for this task.

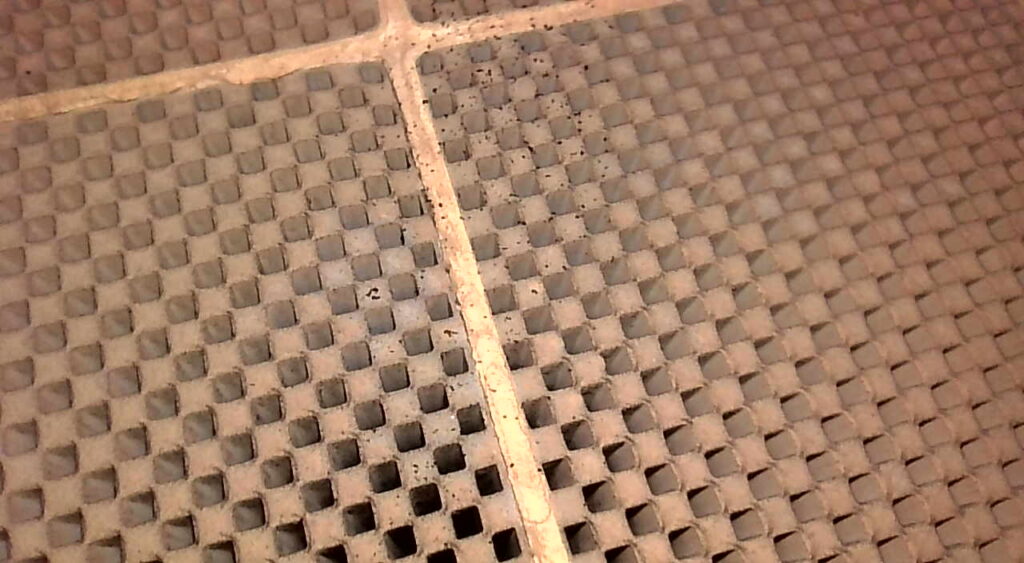

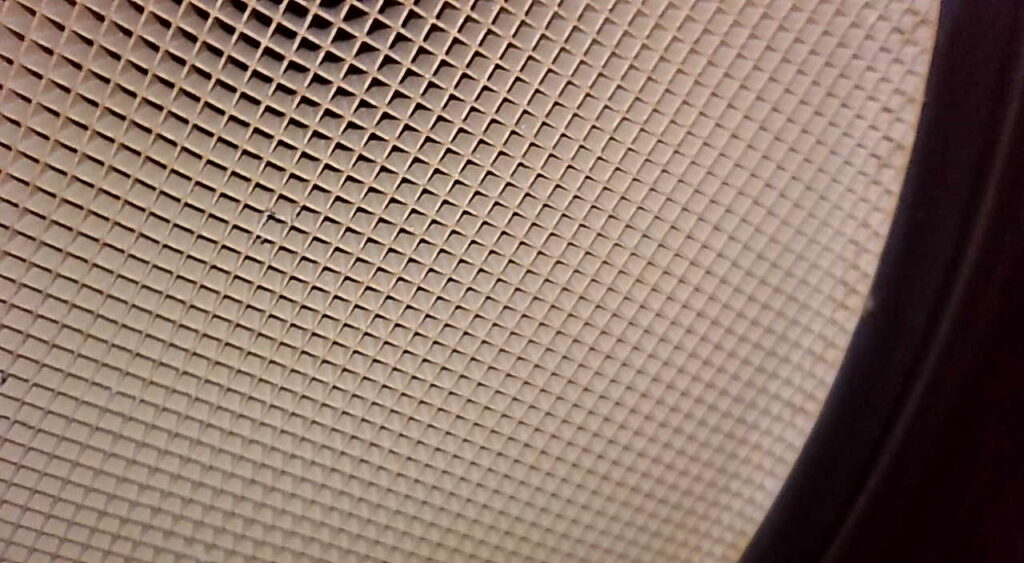

DPD Physical Inspection

Finally a short while ago I decided to just inspect the DPD filter itself. Borrowed a small headed borescope that can take photos and shoved it in all of the available ports on the stack.

Which are:

– Top EGT, has around an 4mm hole, but the camera can see through it and inspect the top of the Catalytic converter. Unable to see the back of the turbo.

– Lower EGT (same 4mm as top), but skip that one.

– As right next to it is the Upper Diff Pressure hardline port. Around 6mm in diameter and will accept a 5mm camera. Great views of the DPD leading face can be found in here.

– Lower Diff Pressure hard line port. Also requires two saddles to be removed.

– Exhaust outlet, can be unbolted and with some issue you can see the backside of the DPD lattice.

Through the Upper diff pressure sensor hard line port I was able to take a handful of boroscope photos. 3 Are bellow. Showing a very clean leading face of the DPD without large soot buildups or burns. You can easily see down the channels throughout. Confirming what had been suspected for a while. That it is not blocked and that some other quackery is ongoing.

3 Images above of the front/top side of the DPF. No Build up or blockage. Does not rule out blockage in the internal channels, just makes it unlikely. Taken through the Diff Press Sensor Hardline Port.

2 Images above for the Catalytic Converter. First of the leading face, second of the rear face.

First taken through the tiny hole for the first EGT Sensor. Second in the same cavity as the leading face of the DPD.

Reverse Sensor Disable / Trailer Plug Reed Switch

One day recently I noted that my reverse sensors haven’t been working in a while. Amazing how you dont notice that quiet loud beep when it is missing. Assumed this was related to the magnetically switched reed switch in the fold down door of the 7-pin flat trailer plug. Checked the wiring and found the magnet was still attached but the reed switch would not short on my multi-meter when the trailer plug fold down door was up (aka no trailer connected). I’m assuming the reed switch or the wire for it that is potted into the trailer connector failed. Shorted a small piece of 1.5mm dia wire from one screw terminal to the other inside the trailer connector and the reversing sensors are now running again. looped the wire to outside the connection. If i need to tow ill either put up with the continual beeping while reversing or cut the wire and add a blade connector pair. Maybe run it up into the cab and add in a panel mount switch. Set to off when towing.

The fail safe logic state for the reed switch seems backwards to me. If the switch or wiring fails id want the car to have the reversing sensors on, not off. A normally closed reed switch in the connector would cost a little more but achieves this. During normal operation. The door is closed, the magnet is close by and pushes the contacts apart, telling the computer no trailer is connected and to use the reverse sensors.

When the trailer connector door is open, the magnetic field is far off and the reed switch returns to its normally closed state, shorting the inputs and telling the computer a trailer is attached. In the event of a wiring or reed switch fault the circuit goes open. The car believes no trailer is connected and only if a user does connect a trailer does it show a problem. That problem being the reverse sensors being activate while a trailer is connected and that maybe they should do something about it?

Initially I was wondering if this is related to the continual regens. If the car thinks it was perpetually towing. Does it increase the frequency of regens regardless of actual engine loads seen? Or it was expecting higher loads, but hasn’t seen them so assumes something else is wrong and regens to compensate. Traced the wires back from the trailer plug to behind one of the panels, passenger side 3rd row. Wires connect directly into a control box for the reversing sensors. This device only had upstream power, ground and a reverse light signal wire. No Canbus connection. So this theory is now thought disproven/unrelated. Plus having now driven for a few weeks with working reversing sensors, the DPD fault didnt recover.

Turbocharger Over Boost Fault

Was given some advise from a mechanic to look for turbo over boosting. Ran my datalogger on the Boost Pressure Variables and looked for wildly higher values on the “Actual” vs “Commanded” Values. Under Load I noted the actual value was rising 15-25kPa above the commanded value and this was an indication of over boosting. I was also getting a small amount of turbo whine, and a higher amount of oil in the intercooler then is reasonable, but even both of these were not enough to investigate the turbo alone alone. As over boosting on the turbo cold side could mean more then an unplanned amount of turbulent flow on the hot side I decided to replace the Turbo in the hopes of it clearing up the regens..

The turbo charger I received as a replacement under warranty in late 2018 was the P/N 8-98317929-3

Not sure on the factory PN of my original turbo. But that -3 variant looks to have been superseded since the warranty job in 2018 by 3 new revisions, now up to 8-98317929-6 which is what I installed.

The Over Boost Fault looked to be the most likely culprit. Creating an inconsistent, or extremely non-laminar, exhaust flow that leaves the vehicle unable to maintain a “DPD Regen End State Learnt” variable. Without this set it does not know what kind of diff pressures it should be seeing after a good regen and has to assume it went badly. Which then, occasionally, throws the P1471 DTC (DPD Insufficient Regeneration) code. In my experience it’ll only throw P1471 with 6km between 2 regens and under highway loads. Loads seen around town allow it to see somewhat of a good end state and not throw P1471. But around town it is still wanting to regen usually less then 12km after the last regen ended.

This turbo replacement ended up not resolving the DPD constant regen fault. The over boosting fault is resolved. “Actual” now lags behind “commanded” boost pressure under most load and the whine is obviously gone.

Other Ideas I have under investigation:

- Incorrect Air cooling paths due to bull bar install, under body protection change from plastic panels to steel. or the open air path around coil over suspension in the front wheel well (came with NVH bumpers from factory but one fell off so the other was removed to match). Basically to much air over the DPD causing it to cool to quickly.

- Bitflip programming error in ECU. ECU check/reflash may be able to resolve if this. Note this vehicle is not modified, chipped or reprogrammed.

- Microfractures in the DPD Diff Pressure line that are not visible under test.

- The clamps that hold the diff pressure lines at each end failing under load.

Closing Remarks

- Personally I feel that this may have been a teething fault with this model being the first to include the DPD and related systems. Either a misunderstood or something that was unable to be simulated.

- Potentially a longevity fault that Isuzu resolved in later models.

- With how much the car relies on technology it does not seem to use that technology very effectively. It seems that either the ECU knows what is wrong, but does not have the codes/means to communicate that to the user.

- Or the ECU is lacking effective programming to determine the fault and report it. With a regen being at the fallback point in whatever programming path it goes down.

- If constant regens are its only way of reporting this fault, even through engine performance never feels sluggish or under powered. Then something is missing in the ECU.

- Constant regeneration of the DPD/DPF has its own issues. From what I’ve heard DPDs have a fixed number of times they can go regen temps in their life. Somewhere in the 8,000-12,000 range, and though I think the past few months have put on an additional 500-600 regens over what it should have that number is wearing away pre-maturely. Based on current kms. and expected distances between before this fault. I believe im sitting around 1,800-2,200 regens total in its life.

- Higher soot dilution into the engine oil. I’ve reduce oil changes to 10,000km between while this fault is ongoing to suit. This adds cost and labor.

- Other issues include higher fuel usage and costs. And, to offset the benefits of this emissions reduction system. More emissions.

As a hypothetical is their an option for an aftermarket SCR product? Something standalone with its own sensors, adblue tank and controller. Just requiring power and an engine on signal to run. Plus an adblue tank low warning light to run into the cab. Sits after the CAT and DPD, a unit that just bolts to the inside of the chassis rail where the exhaust currently passes by. Initial googles suggest no. But that would be an interesting retrofit product ….. that would be expensive and that very little people would buy.

Greetings,

Any solution to the problem found? Mine has just started jumping from zero bars straight to 4 and then in a short while to 5 and into regen but it is every 70km to 100km on average however on the regen it goes down bar by bar till clear.

Regards

G

Good Day to you Lee,

No solution found just yet. Still limping along with it regenerating around every 20-30km.

When it regens it is incapable of getting a good diff pressure sensor reading so the 5 bar display for the DPD “fill level” does not accurately show how full it is, only approx how long to go on the set regen time.

Cheers,

M

Hello Moon, I am glad that I found your blog. I have a December 2017 MUX with 170,000 on car. My car has stopped completely three times on highway. No error codes found in four visits to Isuzu dealers. Regularly needing an operator regeneration of DPF every 70-80 klm, and decreasing as described in supplied car manual. This means that the automatic DPF regeneration is not occurring. I tell the dealer this and they try to tell me this is normal. I agree with your comment that the control module either doesn’t have a code for the fault or how to output the fault code.

Thanks again.

Mate,

You’re a life saver.

Exactly the same issue with my 2017 dmax.

Constant regens even though I was doing 99% freeway driving.

Started driving in 5th gear @ 110kms, took it for a drive in 6th gear threw up P1471.

Deleted code and continued in 5th for another 63km before the Dpf light started again.

130000km since this issue started. 5 workshop computers “(can’t find anything, could be your Dpf, egr, ect)”.

I’ve decided to do the tests myself.

Nope

Changing maf sensor didn’t work.

Long drive Canberra to Melbourne.

5th gear cruise control Dpf every 9 km

17 km for burn to complete 2 x engine light had to reset fault codes to continue. At Glenrowan decided to use 4th gear 110km/ hour just under 3000rpm to Geelong.

No issues with Dpf for approx 230kms.

So I did replace the Maf sensor.

Shortly after, I drove from Canberra to Geelong.

Just before hitting Yass the first burn off flashing light occurred (about 70km).

Things got worse.

About 6km after burn finished it started again, burned for 17 km then started again,and again.

At Glenrowan it threw a wobbly engine light and P1471 reset and kept driving 50km further on threw wobbly again, engine light p1471, p242f. Also threw up traction control light ( seems to only happen when the p242f decides to appear).

Cleared codes decided to drive 4th gear no cruise control the rest of the way 230km approx, no faults.

Drove from Geelong to Mt Gambier, back to the usual faults.

Things I noticed,

Since this issue started some 140,000 kms ago driving in 6th gear made the burn offs more frequent.

5th was some what tolerable.

Now both 5th and 6th gear are bad.

4th gear reving at just under 3000rpm is not pleasant, but doesn’t seem to effect the fuel economy. Still it will go back to constant regens after a while (generally last longer after deleting code ect).

The other thing I find curious, If my Dpf light starts flashing before the 1st or 2nd burn, I’ll have to wait for it to go solid.

After that all I need to do is take my foot slightly off the accelerator to make it change from flashing to solid.

I ended up driving the last 200+ kms home from Mt Gambier in 4th gear, engine light on and a clearly derated engine “ that needed to be driven in 4th to keep @ 110 km/h uphill”.

So I got my Autel out and have done a forced regeneration, and everything seemed to be behaving. Also due to traction control light, checked the wheel sensors computer showed them doing the right thing.

So I guess the manual testing of components is about to start.

I truely feel if the DPF was the issue I would not still be driving the vehicle.

Thanks if you’re reading this .

Bigger thanks if you have any ideas or solutions

A small to medium frown to all who suggest highway driving will solve this issue

My impression: modern diesel, very sensitive, combustion needs to be kept in very good, near-optimal condition to keep/reach long dpf regen cycles. This includes the whole air + fuel intake chain to the engine, the combustion itself and then the exhaust system. Every bit needs to be near-optimally operational. I am not a car mechanic! I only have a single sample with an EU import D-Max, 2013 2.5L 4JK1, 320Kkm

I’ve increased the regen cycle from 80-100km to 260km, but only for a single regen cycle. But it is significant increase, so I think at least one of the changes influenced the distance:

– found a boost leak, fixed it (right before the intake manifold the clamp was skewed)

– cleaned both MAF and MAP sensors (also was measuring desired and actual boost pressure with Otofix D1, Jimmy used one for a D-Max dfp clean: https://www.youtube.com/watch?v=nFWOhQn6A3w)

– even after fixing the boost leak, the boost pressure diff between the desired vs. actual was fluctuating +-10%, will measure soon again (after the MAP clean)

– set proper oil level

– replaced diesel fuel filter (was dirty, pretty much (even clogged?), may have influenced fuel pressure (did not measure), leading to improper combustion, thus more soot gen., or at least ECU believed so which (ECU) controls dpf regen intervals)

– did both oil dilution trip data reset and dpf data reset with Otofix D1 and the former with Isuzu dealer official GIDSS.

– oil change to: Castrol Edge TITANIUM C3 5w-30, here C3 is the important! low ash

– single time added a Liqui Moly Diesel / Injector cleaner (regen distance increase came immediately, so not sure if this influenced at all)

Very low mileage so far, so cannot make hard conclusion from single sample + low mileage 😐

Multiple interventions above I think each can have influence on regen cycle. I also plan to clean injectors, since I doubt any prev. owner did and the truck has 320K.

I hope my long regen cycle stays and I hope at least that much that yours will get longer somehow with or not with these suggestions above.

+ thank you for documenting your case so precisely I think not I am the only one who got big help from your analysis!

Best,

Arpad